Nearly forty companies were on the participants list for the recent site visit organized by BOM to Tracxon on the Hastelweg in Eindhoven. All organizations involved in developing wearables, patches, or textile applications equipped with sensors and electronics. The functions of these applications can be very different, but it's always about translating specific body information into useful data. Heart rate, blood sugar, brain activity, perspiration, everything can be measured. Where this used to be possible only with complex (and large) devices, Holst technology now provides the ability to integrate the sensors into clothing, a patch, or a wristband so that the user hardly notices it anymore.

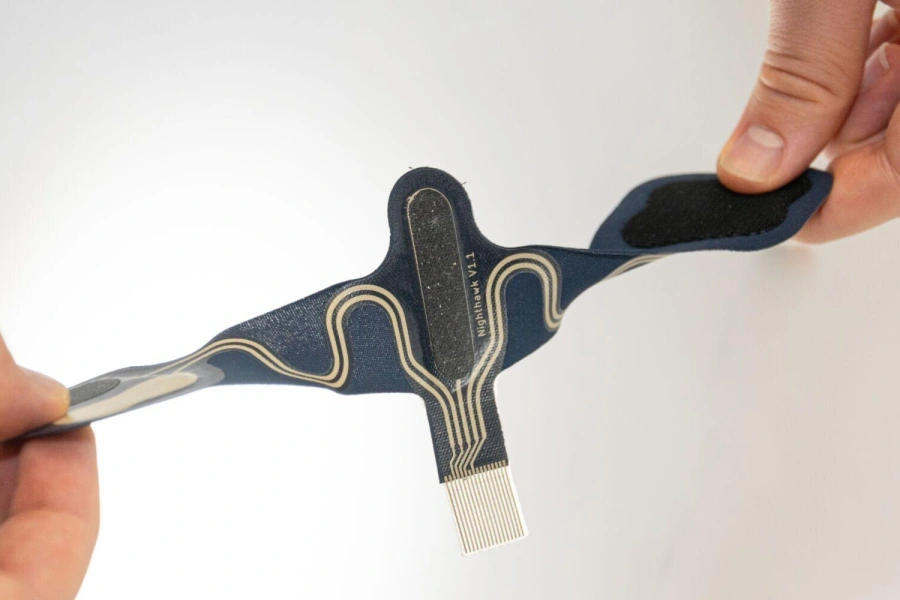

Given the aging population and the shortage of healthcare staff, solutions like these are becoming increasingly important. It enables precise remote monitoring, allowing patients to visit the hospital much less often and enabling doctors to use their time more efficiently. Where electronics in wearables used to be the bottleneck, this hurdle has now been overcome, says Corné Rentrop of Tracxon. “That electronics must be able to move along. It should feel good, fit well, you should be able to shower with it. Thanks to our printed electronics, this is now possible: the result is extremely thin, stretchable, washable, and still with all the functionalities you need for your application.”

Learn more

Business opportunities

The 36 companies that recently visited did not just register to be updated on the latest state of technology, but certainly also for the business opportunities. This means they also have a shared interest. After all, the more companies can do business with Tracxon, the faster that full-fledged Patch Factory can actually get off the ground, and the more there will be a well-functioning local ecosystem.

“It's a bit of a chicken and egg situation,” says Rentrop. “We need to make progress to improve the performance of our process, but to make progress, many customers are needed. And these customers understandably want first the proof that we can indeed handle that scale-up. But for that, we need to make progress.”

To break that impasse, Ria Hein, manager of ecosystem development at BOM, has come into the picture. “We can give a push here and there so that potential partners can actually become part of the value chain. This accelerates innovations and products find their way to the market faster.” The target group for this is innovative SMEs throughout Brabant. “We want to facilitate these SMEs in accelerating steps towards high-quality complex applications. When it comes to medical patches, for instance, they could approach Tracxon. However, with most potential customers, there is still some work to be done before they can make use of this facility. We need to intensify the network to make the innovative possibilities of the Patch Factory more visible and thus inspire parties to come to new product development. After that, the step to the Patch Factory is a logical progression.” All involved recognize the importance of this development, both from societal goals and for business-economic reasons. This is why the shared goals are promising, she adds.

Endurance tests

That’s also confirmed by Coen Lauwerijssen, Director of Product Creation & New Business at 2M Engineering in Valkenswaard. 2M has been collaborating with Holst for some time, but is urgently looking for a company that, preferably nearby, can handle mass production. “This mass production is essential for two reasons,” says Lauwerijssen. “Only by conducting various endurance tests do you uncover problems that you cannot see in a lab environment. So, the more is produced, the faster the quality can increase. Additionally, higher production naturally leads to lower costs.”

To truly become successful, Tracxon needs more than orders from start-ups, Lauwerijssen knows. “For that to happen, corporates also need to step in. If that happens, it would give a boost to the confidence in Tracxon’s solutions, which in turn will attract new parties.” Although those big companies still need to come forward, 2M Engineering is already preparing for that situation. Lauwerijssen: “We will soon create a dedicated website where we will showcase the medical patches we can offer to the market through a contract with Tracxon. And we are also actively discussing with cardiologists about their specific needs. We are already starting on that.”

Well-functioning rcosystem

For Ria Hein, it is an example that makes her happy. “Exactly these kinds of steps are needed to ultimately create that well-functioning ecosystem. This is local for local. Many parties in the region absolutely recognize its importance, as was also evident during their visit to Tracxon. But they must now follow through: the more companies take the steps that 2M is already taking, the faster we can grow. As Brabant, we want to be number one in Europe in the field of Medtech innovations and with the patch factory, we are on the right track.”

Lauwerijssen is hopeful, also because Tracxon has now managed to obtain the medical ISO certification that is necessary for the production of medical devices. “It’s great that Tracxon has come this far. I would therefore like to call on all companies working with this technology to approach them with concrete projects.”

Interview Innovation Origins.

What is the Patch Factory?

The 'Patch Factory' project is a collaboration between TracXon, Holst Centre, Salvia Bioelectronics, BOM, and Elitac Wearables, funded by Stimulus OPZuid, and co-funded by the European Union and the province of Brabant.

The aim of this project is to contribute to accelerating the health transition by creating a complete patch factory. Large Brabant medical companies, SMEs, and start-ups should be helped to realize their health products. Three concrete goals have been defined:

1. Creating an open patch factory for mass-printed electronics in Brabant;

2. Demonstrating the possibilities of the pilot line on pre-selected use cases;

3. Expanding the ecosystem to include more Dutch and European parties and generating a sustainable business model.