That is why pilot factories, among others, are essential. There solutions and techniques that have been researched at the university can be developed and produced into a product. First in a test environment and/or on a small scale, later on a larger scale 'for real'. In other words: solutions are being prepared for the market.

Weaving with organic tissue

Regenerative medicine utilizes the body's own cells, substances, and processes. They strive to enable the body to use its own cells to restore or improve something. An example: a patient's knee is damaged, and they need a prosthesis. Currently, such a prosthesis is often made of ceramics or titanium, but it can be different. For instance, with a 'scaffold', a lattice work of biomaterial, in the shape of the missing or damaged body part. The body's own cells, in this case cartilage, then grow over this latticework. Eventually, the scaffold dissolves or is accepted by the body. And the patient has a 'real' functioning knee again.

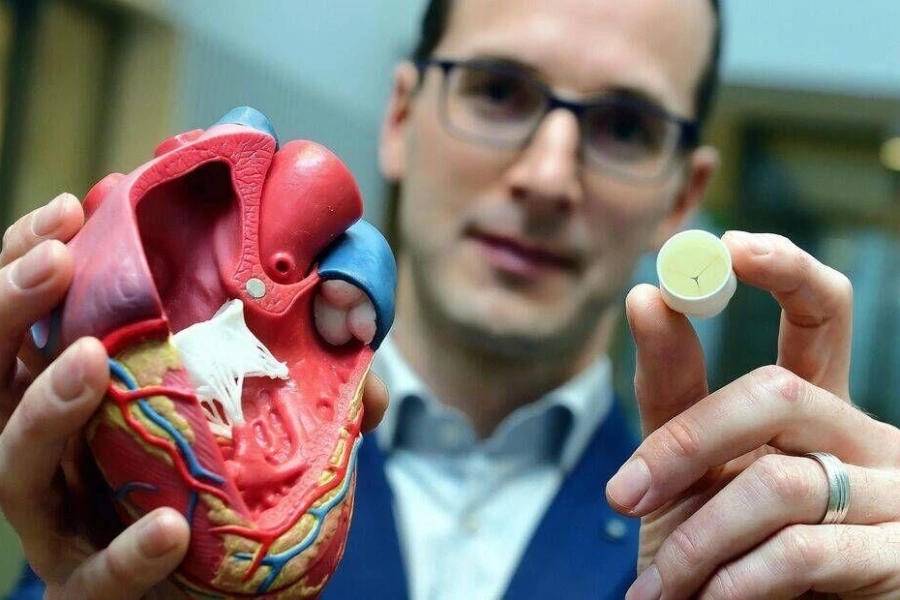

That is where healthcare aims to go in the future. And a knee is just one example. Various techniques, biomaterials, and applications are being researched. For instance, the Dutch-Swiss startup Xeltis is developing a heart valve based on polymers. And VivArt-X is working on a synthetic biomaterial to form healthy breast tissue after breast surgery.

SBMC: powerful collaboration in the ecosystem

In 2021, BOM, the TU/e, and the Province of North Brabant signed for the establishment of the Smart BioMaterials Consortium (SBMC): a public-private partnership focused on the realization of facilities for the accelerated development and commercialization of biomaterials.

Ria Hein, Program Manager Life Sciences & Medtech: “As the Ecosystem Development team, we have talked to many companies in the Life Sciences & Health sector. What exactly did such a new 'pilot factory' need to meet? We have inventoried all the wishes and needs for development and production facilities. The pilot factory is being set up based on that. In the meantime, the SBMC has become a close-knit community of over 60 companies.”

According to Ria, launching a supply-driven facility in the market usually doesn't work. “The SBMC contributed to how the pilot factory should look. The advantage is that these companies will actually want to use the facilities. And that the factory truly becomes embedded in the business world. This makes this Brabant facility unique.”

Nationaal Groeifonds and Regmed XB

Through the National Groeifonds, the government is investing in projects between 2021 and 2025 that ensure long-term economic growth. Regenerative medicine based on biomaterials has a lot of potential. For the economy and public health. That is why Regmed XB was established in 2016. This partnership stimulates research to accelerate the long road to healing. From the National Groeifonds, Regmed XB will receive a grant of € 56 million in 2021 to realize so-called 'pilot factories' for regenerative medicines. This grant is also an additional boost for the realization of SBMC and the availability of the facilities.

Brabant pilot factories

Since October 2021, one branch of the pilot factory has been located on the campus of the Eindhoven University of Technology, equipped with research & development facilities. This helps companies to explore how they can bring their idea into production. Once this has been successfully achieved on a small scale in the development facility, they are expected to be able to move to the new (pilot) production factory on the High Tech Campus in Eindhoven from the first quarter of 2025, for larger-scale production. The new location will have four cleanrooms, with a total area of 400 square meters, a laboratory for quality control, offices, and storage space.

Taking regenerative medicine to the next level

The pilot factory in Eindhoven is truly becoming an open innovation environment. By allowing companies to use the facilities and equipment of the shared facility, they do not have to invest in expensive equipment themselves. This way, the SBMC aims to elevate the production and processing of biomaterials and biodegradable implants to an industrial level. Consequently, we will soon have access to large numbers of therapies in Brabant that are suitable for the global market.

Jan Rietsema, CEO of SBMC: "In the Brainport region, we are very skilled at developing new ideas for regenerative medicine, but the path to the patient is long and challenging. BOM brought together a diverse cluster at the SBMC that truly commits to the goals of the SBMC: the future of biomaterials. Not only life sciences companies that develop biomaterials but also high tech companies that excel in industrializing the necessary processes and technologies. Our ultimate goal is to accelerate the process from patent to patient. This is good for the patient as well as for the startups in Southeast Brabant that are leading in the development of biomaterials for regenerative medical applications. Like Xeltis, STENTiT, and VivArt-X. Companies from inside and outside the consortium are welcome to become active in our shared facilities and utilize our expertise to further address their scaling and production challenges."

Three core competencies of BOM come together

All three core competencies (developing, investing, and internationalizing, ed.) come together in the Smart BioMaterials Consortium.

Ria: “The Ecosystem Development department brought parties within the ecosystem together and helped build the close-knit community that the Smart BioMaterials Consortium is today. We also ensured governance for the development and production facilities of the pilot plant.”

BOM acts as an investor for companies within the SBMC, for instance, with STENTiT, VivArt-X, and Vivolta. Mercedes Tuin, Investment Director Life Sciences & MedTech at BOM: “This enables these companies to grow from startup to scale-up. They bring innovative products to the market, helping patients with, for example, cancer or cardiovascular diseases. We also support by providing access to our network of other investors.”

Half of the total Dutch production value in Life Sciences & Health (about ten billion euros) already accounts for North Brabant. It also has international appeal. The Internationalization Team uses the SBMC as part of the soft-landing program for foreign companies. They look for companies that fit into our ecosystem and ensure that they establish themselves in Brabant. The close-knit community in the ecosystem and the development and production facilities of the pilot plant are enormous USPs for our province. Universities around the world conduct research into regenerative medicine and biomaterials, but the technology is still young and not many companies are yet working on bringing it to practical application. The presence of research, production, logistics, and a strong network in a relatively small geographical area is something to be proud of.”